Ognjen Regoje

But you can call me Oggy

I make things that run on the web (mostly).

More ABOUT me

and my PROJECTS.

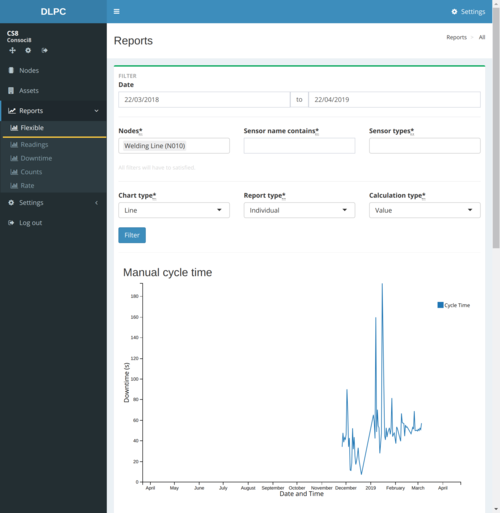

Factory monitoring and inventory system

| Usage | Continious monitoring | Problems detected |

|---|---|---|

| ~2000 different bills of materials tracked |

~30 heavy presses for several months |

At least 20 instances where an alert prevented prolonged downtime |

DLPC consists of two parts: one receives data from press sensors that is then used to calculate stats, the second is for tracking of inventory through bill of materials

Rails and MySQL for the backend and Python for the sensor firmware originally prototyped on Raspberry Pi. Nodes send data through MQTT run by Rabbit. DC.js for graphs.

A manufacturer of metal parts in the automotive industry that operated a large factory with many heavy presses and other machinery.

Part of DLCPs focuses on generating realtime and historical stats. Numbers calculated include downtime, acceptance rates as well as overall equipment effectiveness (OEE), a crucials statistic in the manufacturing sector to ensure optimal equipment usage.

DLCP tracks realtime and historical cycle times. It has two ways of triggering alerts. First, through once values fall outside of automatic z-score based ranges, and second once a user specified manual or relative tresholds are reached. DLCP can alert using email, SMS and browser push.

DLCP also is able to track various assets and their bill of materials. It can track incoming delivery orders. It shows inventory status based on real stock levels as well as based on conversions through bill of materials. It also supports multiple warehouses and indicates where the stock is kept.s